As companies and designers from the furniture industry search for new applications and experimenting with more sustainable materials, they finally discovered the benefits of 3D printing Australia.

Though the majority of the furniture today is mass-produced using traditional fabrication methods, many companies are already using 3D technology to produce high-end pieces of furniture.

Today, popular furniture brands utilize this technology to design and create furniture that features complex geometries which are impossible or difficult to manufacture using molds.

These current projects by high-end furniture companies clearly show the potential of 3D print technology for interior design.

We will discuss in this article the different uses, benefits, and advantages of 3D printing to the furniture industry.

Capability to Design Unique and Stunning Models

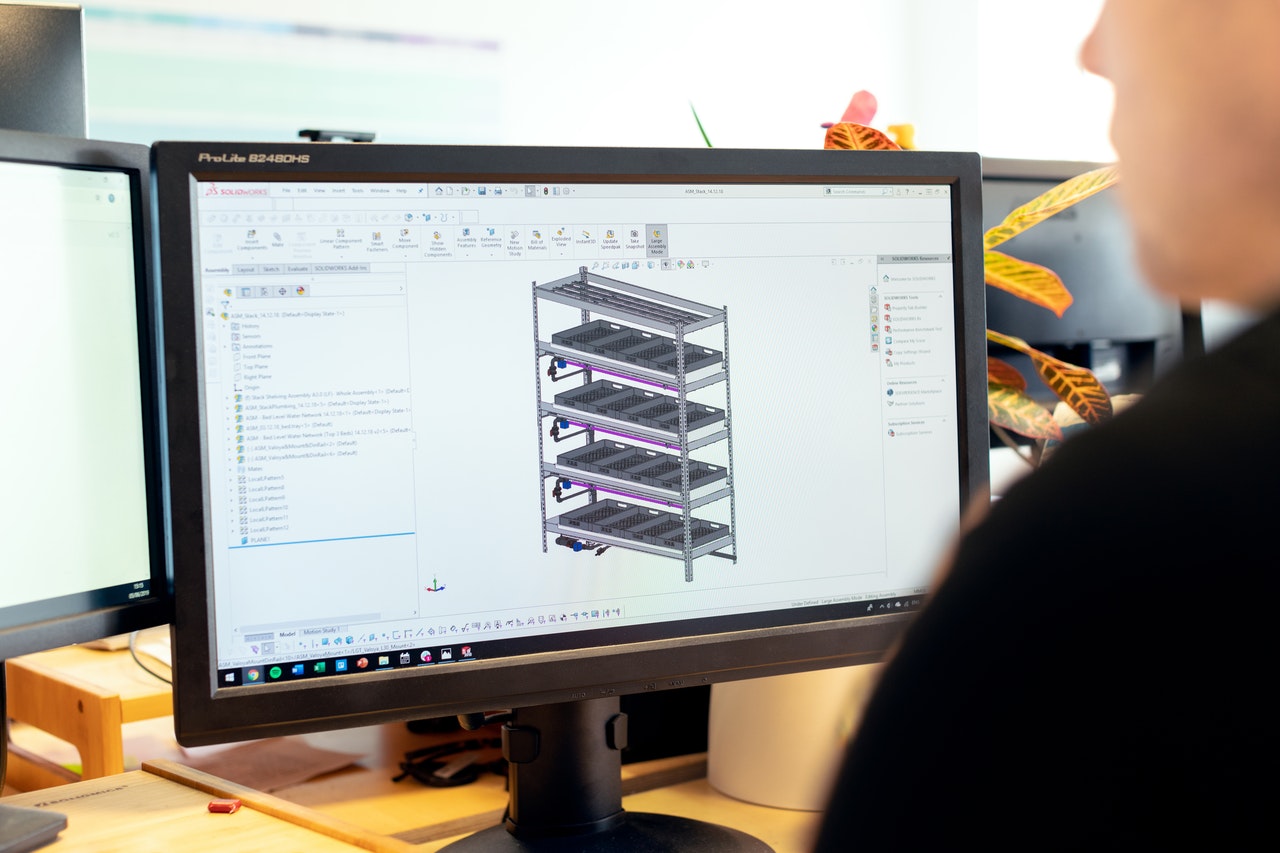

By utilizing 3D modeling tools and software, furniture designers can easily and quickly design unique and original models. There are common furniture styles that everyone knows. However, with 3D designing, designers can enjoy endless possibilities and design freedom.

Clients may also collaborate with designers in creating unique art pieces by using different forms and mediums to enhance the interior of their houses and add value to their properties.

Option to Create an Entire Furniture or by Individual Components

With 3D print technology, furniture manufacturers can create and produce the entire piece of furniture or design them individually and assemble them afterward. The benefits of having this option or procedure are pretty obvious.

Additionally, there are limited restrictions in terms of innovative and creative design compared to the traditional methods. Designers can also benefit from the flexibility and freedom in choosing what materials they will use. Plus, very little waste is produced using this manufacturing method.

Ability to Fabricate Lightweight Furniture

For some of us, moving and rearranging furniture inside our house can be challenging, especially if they are heavy. So, most people choose to sell their furniture every time they change residence or relocate to far places rather than burdening themselves with transporting them.

Also, for this very reason, customers prefer lightweight furnishings. You might be wondering, how would this be even possible when wood and metals are essential components in manufacturing home furniture?

With the help of 3D modeling software, it becomes possible to fabricate durable and lightweight furniture pieces by decreasing their mass. And by using suitable materials, it is easy and feasible to design these types of furniture pieces.

The Future of 3D Printing Australia in the Furniture Industry

With the low production costs and the limitless design options of 3D technology, it’s no surprise that it will take the furniture industry by storm.

Also, it would be possible in the future where customers can look at the pieces of furniture online, have them printed, and pick them up the next day.

Lastly, like all industries, the furniture industry will face many significant changes in the future as the world starts to adapt to this new technology.