Many modern-day experts capitalize on using this 3D printing technology on a long-term basis. Modern technology is continually developing, along with numerous businesses in which this printing is utilized. So, let’s discover how the pertinence of this technology has extended in certain occupations and respond to the question concerning 3D printing today.

3D Printers in Different Fields

Product Layout

The fashion group is a family member novice to the industrial use of 3D printing aside from prototyping items for advertising and marketing purposes. New Balance’s product developers have used careful laser sintering technology integrated with specially created new powder components produced in partnership with 3D Solutions. A striking instance of the development is Zante Generate, running footwear featuring a full-length thermoplastic midsole of extraordinary efficiency and incredible versatility.

Environmental Engineering and Architecture

Ecological designers and civil fitters get on the edge of one of the critical and timely uses of mobile printing resolutions. A great example is the Area Prepared humanitarian organization. After an earthquake, two designers utilized their Land Vagabond as a standing system and a charger to a bit of desktop computer 3D printer.

Clinical Market

The future of high-dosage medications has taken a quick crumbling form with ZipDose technology that is developed by Aprecia’s pharmacologists. The accurate powder-liquid layering that allows producing the one-of-a-kind bonds system, masking the preference, simplifies medicine administration and makes it possible to recommend specific dosages to people.

Automotive Sector

Have you fantasized that someday you’ll be able to make not just car components but the entire car utilizing 3D printers? Well, the makers of STRATI have equated these dreams right into a fact, and also, it symbolically happened in Detroit!

Food Sector

Cooks and also restaurateurs are simply fans of novelties such as Foodini. This portable machine can develop a healthy and fresh, and balanced meal in the quickest and amazing means. Foodini is a technology that can be utilized much like a microwave. All-natural equipment designers gave it an open capsule version that allows this home appliance to be much more practical and multi-purpose than competitors’ gadgets.

Music

Musicians across the globe instantly actually make use of 3D printing as an inexpensive method to get top-quality innovative instruments. Amongst the extraordinary ones, we should mention a steel saxophone published by fanatic Olaf Diegel after previous tryouts of the Duraform drum set and nylon guitar.

Artists

As opposed to detailing a lot of 3D published drums, cellos, guitars, violins, and even brought back plastic documents in addition to playing songs servo motors, let’s examine various other uses of 3D printing in a larger selection of arts—Mark Wilson’ newest job borders with the formation of a brand-new life.

Professionals, both from huge and tiny firms, artists, researchers, developers, engineers, and architects, choose this innovation not just to attempt something new but also various. They choose it as a result of cheaper non-waste manufacturing, simplified manufacturing procedures, the opportunity to use recyclable materials, simpleness and movement, environmental kindness, and limitless shapes and sizes of items.

Touch screen display as modern technology

Touch screen display as modern technology

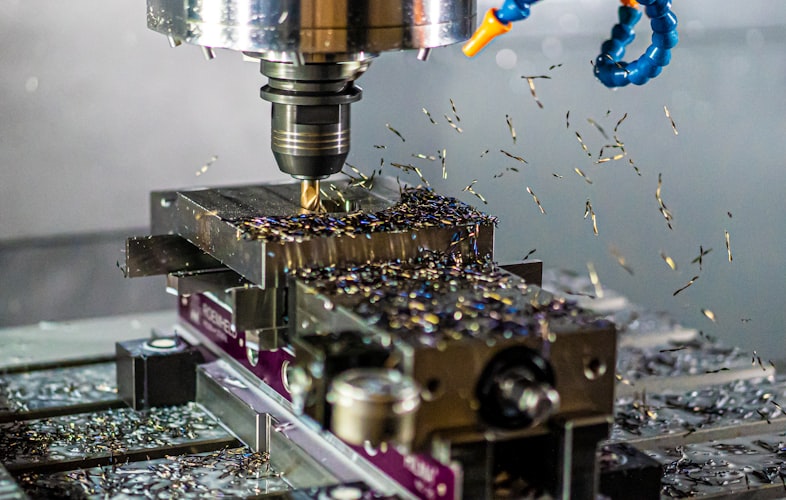

Before, only one piece of metal could be cut at a time using a saw or other mechanical metal cutting technique. It is time-consuming and costly, too. Today, the metal fabrication and manufacturing industry employs technology-based cutting systems like computer-controlled waterjet and abrasive jet cutting to cut a variety of soft and hard materials.

Before, only one piece of metal could be cut at a time using a saw or other mechanical metal cutting technique. It is time-consuming and costly, too. Today, the metal fabrication and manufacturing industry employs technology-based cutting systems like computer-controlled waterjet and abrasive jet cutting to cut a variety of soft and hard materials. Imagine using digital screens in your sessions that function like large iPads. Would not conferences and functioning sessions be much more interesting than with an ‘old school’ projector or TV screen? Wouldn’t your workshops be a lot more appealing and approximately modern-day standards than with physical sticky notes and whiteboards?

Imagine using digital screens in your sessions that function like large iPads. Would not conferences and functioning sessions be much more interesting than with an ‘old school’ projector or TV screen? Wouldn’t your workshops be a lot more appealing and approximately modern-day standards than with physical sticky notes and whiteboards?

There is no disputing on this one that 3-dimensional printing has impacted the manufacturing world in many ways. Taking things from the perspective of an engineer, 3D printing (sometimes referred to as additive manufacturing) has provided a better alternative to building/creation of various physical objects.

There is no disputing on this one that 3-dimensional printing has impacted the manufacturing world in many ways. Taking things from the perspective of an engineer, 3D printing (sometimes referred to as additive manufacturing) has provided a better alternative to building/creation of various physical objects.